In the highly demanding environment of hydraulic fracturing operations, pump efficiency and equipment reliability are critical to project success. Fracturing pump packing, a core component of high-pressure pumps, plays a pivotal role in ensuring stable performance and reducing operational downtime. WDF-Seals, headquartered in Guangzhou, China, specializes in advanced sealing solutions engineered to withstand extreme pressure, abrasion, and chemical exposure. Their extensive R&D capabilities and material expertise, including over 10,000 proprietary formulations, have positioned the company as a leading supplier for global oilfield service providers.

This article explores how WDF-Seals fracturing pump packing enhances hydraulic fracturing efficiency and contributes to reduced downtime by optimizing durability, sealing performance, and operational stability under harsh conditions.

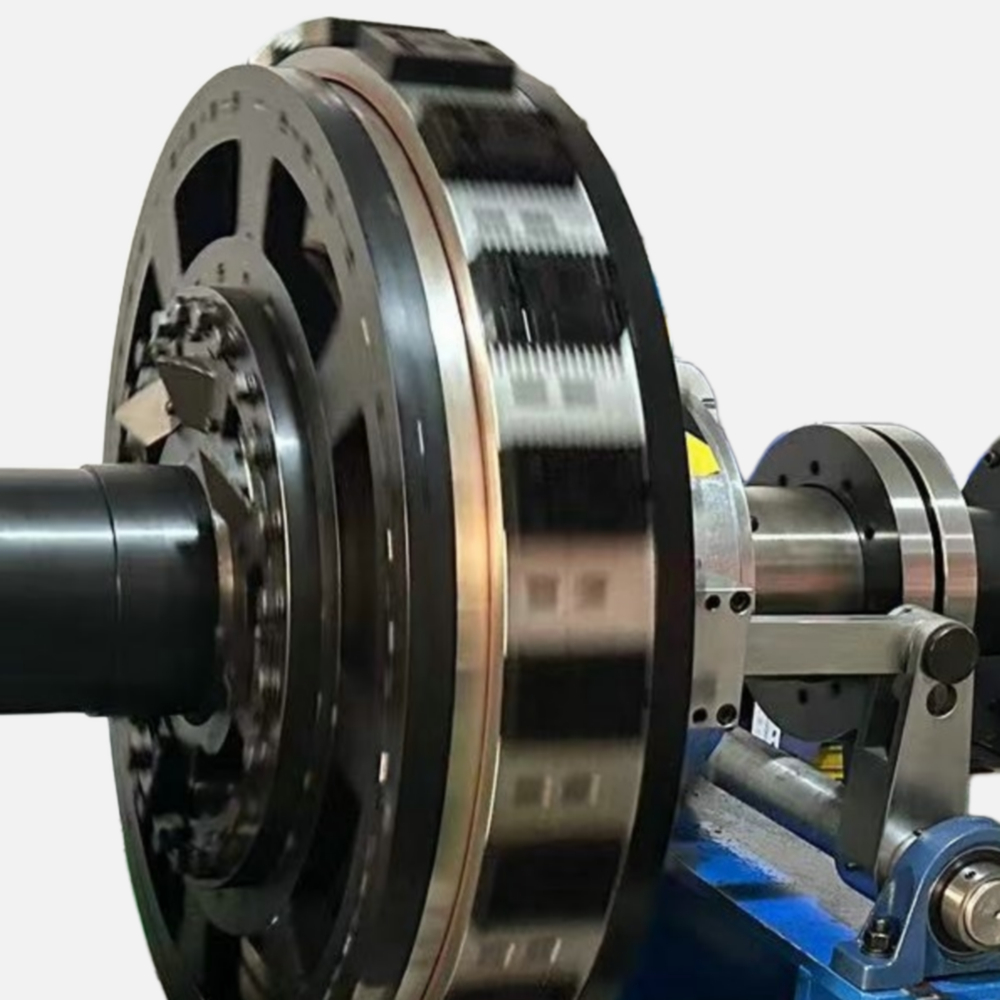

Key Features of WDF-Seals Fracturing Pump Packing

High-Pressure Resistance

Hydraulic fracturing pumps operate under extreme pressures, often exceeding 175 MPa. WDF-Seals packing is specifically engineered to maintain integrity under these conditions:

-

Header Ring and Pressure Rings: Designed to evenly distribute hydraulic loads.

-

Wiper Seal: Ensures consistent sealing even during high-pressure cycles.

-

Material Strength: Selected for resistance to extrusion and deformation at high pressures.

By maintaining a robust seal at peak pressures, the packing prevents leakage, minimizes energy loss, and ensures consistent fluid injection, directly improving fracturing efficiency.

Wear Resistance

Hydraulic fracturing involves pumping sand-laden fluids, creating severe abrasive conditions. WDF-Seals packing demonstrates:

-

Exceptional durability against coarse and fine sand particles.

-

High wear resistance to reduce the frequency of replacements and maintenance.

-

Extended service life, leading to fewer interruptions in operations.

The high abrasion resistance ensures that pumps maintain optimal performance, even under continuous operation, minimizing downtime and improving productivity.

Temperature Tolerance

During hydraulic fracturing, frictional heat and fluid temperature fluctuations can compromise traditional packing materials. WDF-Seals packing exhibits:

-

High thermal stability, sustaining performance under elevated temperatures.

-

Low-temperature adaptability, preventing shrinkage or cracking in colder operational environments.

-

Consistent elasticity, enabling reliable sealing regardless of temperature variations.

This thermal resilience guarantees uninterrupted pump function and consistent fracturing performance, even in challenging field conditions.

Corrosion and Chemical Resistance

The fluids injected during hydraulic fracturing often contain acids, salts, and other corrosive substances. WDF-Seals packing is formulated for:

-

Resistance to HCl, water, seawater, sand, mud, and salt.

-

Chemical stability, preserving material integrity over repeated exposure cycles.

-

Enhanced lifespan in harsh chemical environments, reducing the risk of operational failure.

By combining corrosion resistance with wear and pressure resilience, the packing ensures continuous, leak-free operation.

Impact on Hydraulic Fracturing Efficiency

The advanced properties of WDF-Seals fracturing pump packing translate into measurable operational benefits:

-

Improved Flow Stability: Reduced leakage ensures precise fluid injection and consistent fracturing pressure.

-

Higher Pump Efficiency: Less energy loss due to leakage and friction leads to improved pump output.

-

Reduced Maintenance Intervals: Durable packing minimizes the frequency of replacements.

-

Extended Equipment Lifespan: Reduced wear and corrosion prolongs the operational life of pumps.

Industry research indicates that high-performance pump packing can reduce downtime by up to 30%, directly impacting project timelines and cost-efficiency.

Installation and Maintenance Best Practices

To maximize efficiency and lifespan:

-

Proper Assembly: Ensure header rings, pressure rings, and wiper seals are correctly aligned.

-

Regular Inspections: Monitor for wear, deformation, or chemical damage.

-

Timely Replacement: Replace packing before significant wear affects pump performance.

-

Compatibility Checks: Match packing materials to the specific hydraulic fluid and sand concentration used in the operation.

Following these best practices ensures that WDF-Seals packing consistently delivers high performance and minimal downtime.

Application Scenarios

WDF-Seals fracturing pump packing is ideal for:

-

Onshore and offshore oil fields requiring high-pressure, high-resilience seals.

-

Hydraulic fracturing operations in shale formations with abrasive slurry conditions.

-

High-temperature or chemically aggressive environments, including acidizing and water injection operations.

-

Projects requiring long operational hours without frequent maintenance, such as large-scale oil and gas extraction sites.

These applications demonstrate the packing’s versatility and reliability across diverse field conditions.

FAQ

Q1: Can WDF-Seals packing handle extreme pressures over 175 MPa?

A1: Yes, the packing is engineered for ultra-high pressure hydraulic fracturing pumps.

Q2: How does wear resistance reduce downtime?

A2: Durable materials resist abrasion from sand and slurry, extending service intervals.

Q3: Is the packing chemically resistant?

A3: Yes, it withstands HCl, seawater, mud, and various other corrosive substances.

Q4: Does temperature variation affect performance?

A4: No, the packing maintains sealing integrity under high or low operational temperatures.

Conclusion

WDF-Seals fracturing pump packing offers a comprehensive solution for enhancing hydraulic fracturing efficiency while reducing downtime. Through a combination of high-pressure resistance, wear resistance, thermal stability, and chemical durability, it ensures stable pump operation even under the most challenging conditions.

As a leading manufacturer of industrial sealing solutions, Guangzhou WDF-Seals Technology Co., Ltd. leverages decades of R&D experience and material expertise to provide reliable, high-performance pump packing for global oilfield operations. Implementing WDF-Seals packing ensures that hydraulic fracturing projects run efficiently, safely, and cost-effectively.

www.wdfseals.com

Guangzhou WDF-Seals Technology Co., Ltd.