In industrial environments where extreme heat, pressure, and aggressive media are common, selecting the right sealing solution is critical to ensuring equipment reliability and long-term performance. High temperature PTFE wedge seals are widely used in applications such as chemical processing, power generation, oil and gas, and high-performance machinery due to their excellent thermal and chemical resistance. However, not all PTFE wedge seals are created equal. Understanding the key factors behind their selection can help you optimize performance, reduce downtime, and extend equipment life.

1. Temperature Resistance and Thermal Stability

The primary reason for choosing PTFE wedge seals is their ability to perform under high temperatures. Standard PTFE can typically withstand continuous temperatures up to around 260°C (500°F), while modified or filled PTFE compounds may offer improved thermal stability and reduced creep at elevated temperatures. When selecting a seal, it is important to consider both the maximum operating temperature and temperature fluctuations, as repeated thermal cycling can affect sealing performance over time.

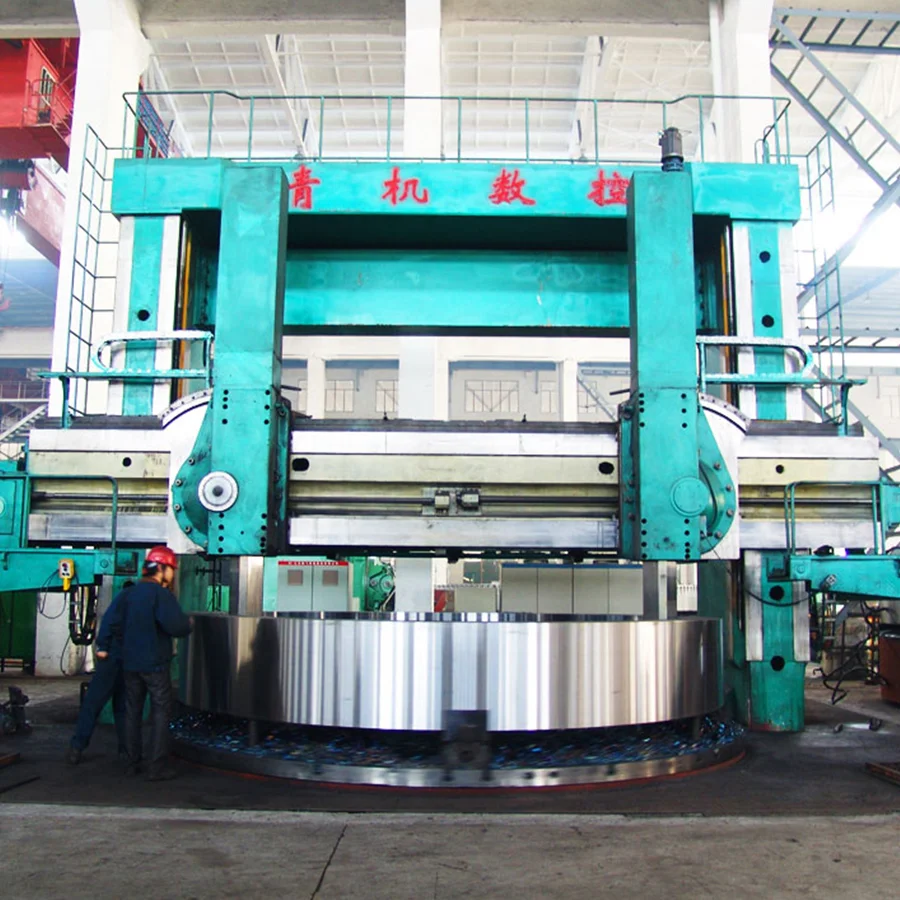

2. Pressure and Mechanical Load Requirements

High temperature applications often involve significant pressure or mechanical stress. PTFE wedge seals rely on their wedge-shaped profile to generate sealing force when pressure is applied. The seal design, material hardness, and extrusion resistance must be matched to the system pressure to prevent deformation or seal failure. Reinforced or filled PTFE materials can provide better load-bearing capability in demanding operating conditions.

3. Chemical Compatibility

One of PTFE’s biggest advantages is its near-universal chemical resistance. However, fillers added to enhance mechanical strength or wear resistance may slightly alter chemical compatibility. It is essential to evaluate the process media, including chemicals, gases, or lubricants, to ensure long-term seal integrity. Proper material selection minimizes swelling, degradation, and unexpected leakage.

4. Seal Design and Dimensional Accuracy

Precision in seal design directly impacts performance, especially in high temperature environments where thermal expansion occurs. Accurate dimensions, smooth surface finish, and consistent wedge geometry help ensure uniform load distribution and effective sealing. Custom-designed wedge seals may be required for specialized equipment or non-standard grooves to achieve optimal results.

5. Wear Resistance and Service Life

In dynamic or semi-dynamic applications, wear resistance becomes a key consideration. High temperatures can accelerate wear if the seal material is not properly formulated. Filled PTFE compounds, such as those reinforced with glass fiber, carbon, or bronze, can significantly improve wear resistance while maintaining excellent heat tolerance, extending service intervals and reducing maintenance costs.

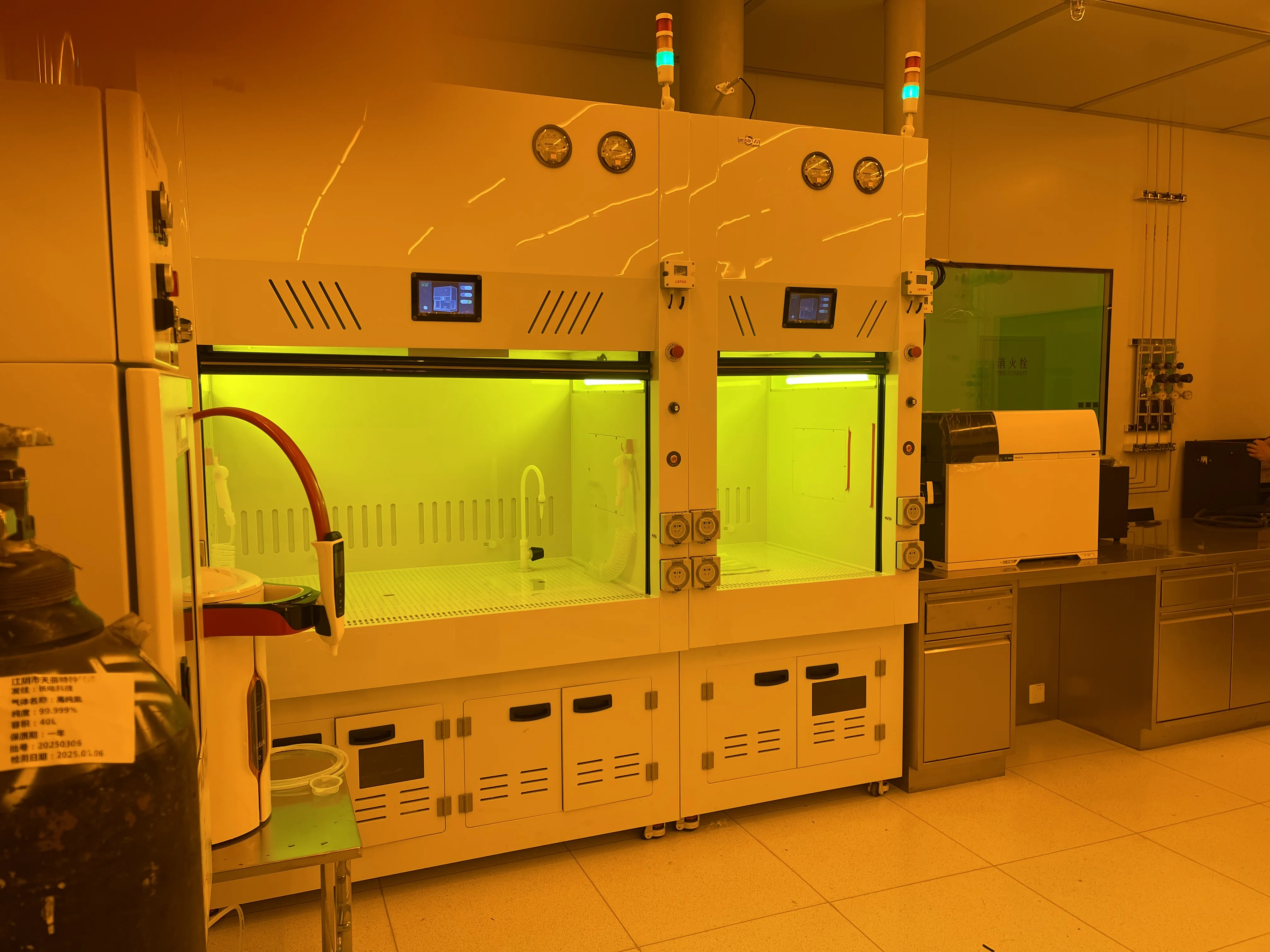

6. Manufacturing Expertise and Quality Control

The performance of high temperature PTFE wedge seals depends not only on material choice but also on manufacturing quality. Partnering with an experienced manufacturer ensures consistent material formulation, precise machining or molding, and rigorous quality control. Ningbo Wecan Seals Co., Ltd., as a professional sealing manufacturer and exporter with its own factory, focuses on the research and production of high-quality mechanical seals and sealing solutions. Their in-house production capabilities allow for strict control over materials, dimensions, and performance standards, ensuring reliable sealing solutions for demanding industrial applications.

7. Customization and Technical Support

Different industries and equipment designs often require tailored sealing solutions. The ability to customize PTFE wedge seals based on operating temperature, pressure, media, and installation conditions is a major advantage. A manufacturer that offers technical consultation and application-specific recommendations can help prevent costly design mistakes and improve overall system efficiency.

Conclusion

Choosing the right high temperature PTFE wedge seal involves more than simply selecting a heat-resistant material. Factors such as pressure resistance, chemical compatibility, seal design, wear performance, and manufacturing quality all play a critical role in achieving reliable and long-lasting sealing. By working with an experienced and specialized manufacturer like Ningbo Wecan Seals Co., Ltd., equipment operators and engineers can ensure they receive high-quality, customized sealing solutions that meet the toughest operational challenges and deliver dependable performance over time.

www.wecan-seals.com

Ningbo Wecan Seals Co., Ltd.