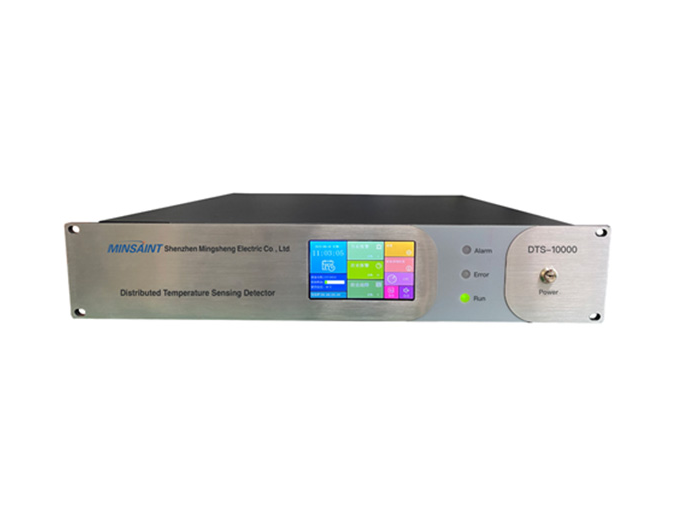

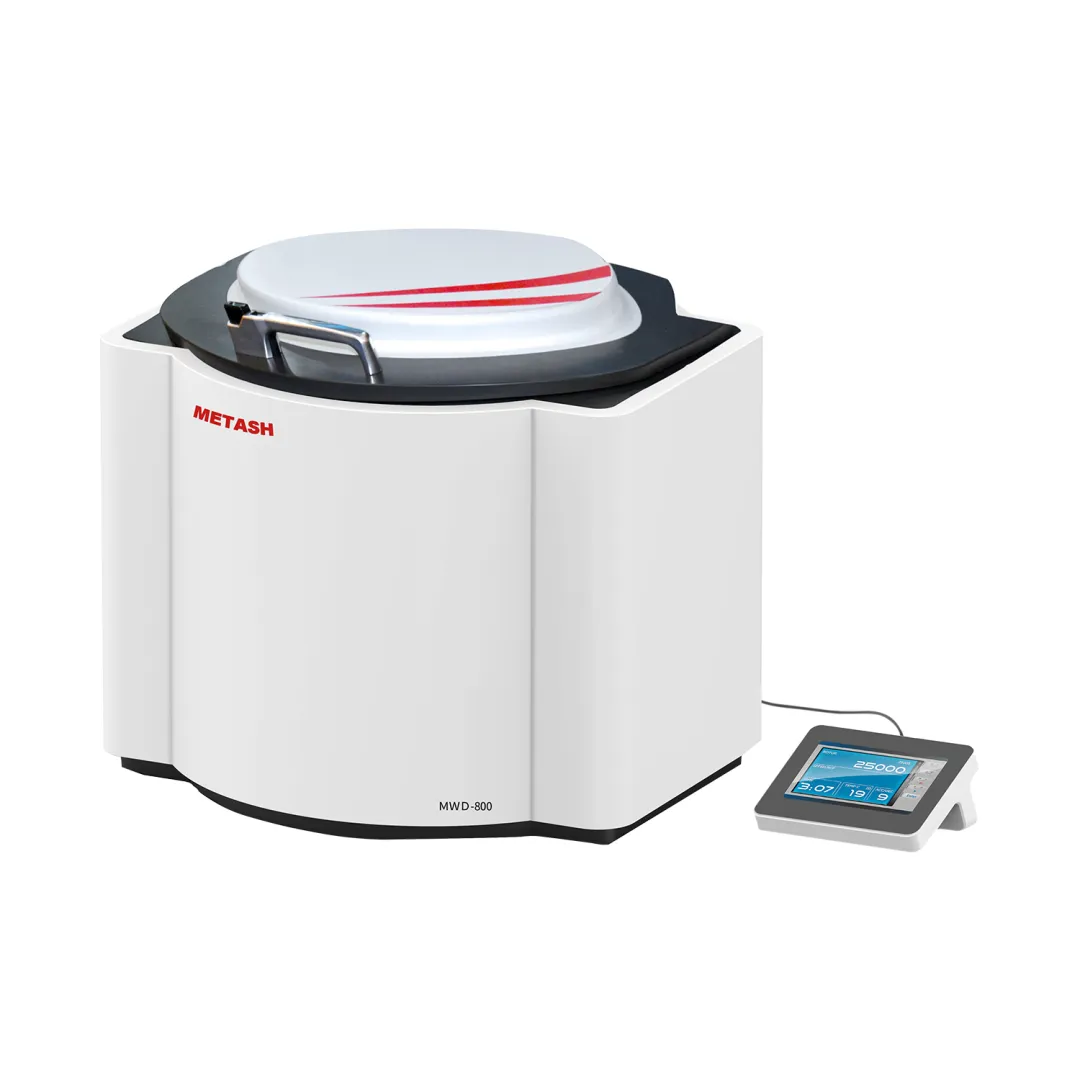

A microwave digestion system has become an indispensable tool in modern analytical laboratories, supporting precise elemental analysis across environmental, pharmaceutical, food, chemical, and materials research fields. With rapid digestion capability, robust safety design, and advanced monitoring technology, this equipment delivers consistent sample preparation quality while significantly improving laboratory productivity. In this blog post, METASH, as high quality microwave digestion units exporter, will share its high performance microwave digestion system for accurate and efficient sample preparation.

High-Performance Microwave Digestion System Overview

A high-performance microwave digestion system uses controlled microwave energy to decompose complex matrices into clear solutions suitable for spectroscopic analysis. Compared with traditional hot-plate digestion, microwave technology delivers faster heating, superior temperature control, and higher reproducibility.

This section introduces the system' s overall architecture, explains how microwaves enhance digestion efficiency, and highlights why laboratories increasingly rely on automated digestion platforms for high-throughput workflows.

Advanced Microwave Digestion Technology and Working Principles

Modern microwave digestion technology applies electromagnetic radiation to heat reagents and samples uniformly within sealed vessels. This controlled high-pressure environment significantly accelerates sample breakdown while maintaining chemical integrity.

The system typically integrates:

* Magnetron microwave source

* PTFE or high-strength composite digestion vessels

* Contactless temperature and pressure sensors

* Automated control algorithms to adjust microwave output

* Multiple safety interlocks

By maintaining a stable thermal and pressure profile, the digestion process becomes highly predictable and reproducible, ensuring reliable analytical outcomes.

Batch Processing with Up to 40 Digestion Vessels

One of the defining advantages of this batch microwave digestion instrument is its ability to accommodate up to 40 sample vessels simultaneously.

This capability is especially valuable for laboratories handling:

* Environmental soil and sludge testing

* Food and feed quality analysis

* Pharmaceutical raw material verification

* Metal alloy composition studies

High sample throughput dramatically reduces total preparation time, supporting large-scale routine testing without compromising digestion quality or consistency. It also minimizes instrument idle time and reduces the per-sample cost of analysis.

Specialized Digestion Vessel Design for High-Pressure Conditions

The system features specially engineered digestion vessels that enhance performance and user safety. Each vessel incorporates:

* Automatic venting mechanism

* Self-resealing pressure-release structure

* Chemically inert, corrosion-resistant materials

When a sudden over-pressure situation occurs, the vessel releases internal pressure instantly and reseals without operator intervention.

This innovative design reduces the risk of vessel damage, prevents sample loss, and ensures continuity in multi-sample batches. It is especially beneficial when dealing with challenging matrices such as polymers, bio-samples, oils, mineral ores, or refractory materials.

Contactless Temperature and Pressure Monitoring in Microwave Digestion

Precision control is central to any high-performance microwave digestion equipment. This system incorporates contactless infrared temperature sensors and pressure sensors to monitor real-time conditions inside each digestion vessel.

Key Technical Advantages:

* Measures actual sample solution temperature, not simply vessel wall temperature

* Achieves true one-to-one monitoring for all vessels

* Avoids cross-contamination risk associated with invasive probes

* Displays real-time T/P data throughout the digestion cycle

* Enhances digestion reproducibility in multi-matrix workflows

This sensor technology ensures complete transparency during digestion and enables operators to confirm safety conditions and digestion completeness at any time.

Flexible Method Programming and Large Storage Capacity

For laboratories processing diverse sample types, this programmable microwave digestion system offers a comprehensive method library.

Method programming features include:

* Storage of up to 255 customized digestion methods

* Each method supports up to 10 programmable steps

* Adjustable parameters include:

Temperature

Pressure

Ramp and hold time

Microwave power output

This flexibility is crucial for optimizing digestion conditions for matrices such as plant tissues, metals, wastewater, industrial chemicals, plastics, pharmaceuticals, and geological samples.

Users can build a standardized method library, ensuring consistent results across operators and projects.

Multi-Layer Safety Protection in Microwave Digestion Systems

Safety is a core design principle in any microwave digestion unit. This system integrates multiple layers of protection to safeguard users and maintain stable operation.

Comprehensive safety configurations:

* Double-locked security door to prevent accidental opening

* Real-time temperature and pressure supervision for every vessel

* Automatic control for over-pressure and over-temperature conditions

* Abnormal sound detection to identify unexpected mechanical or chemical activity

* Intelligent system shutdown in case of critical alerts

These mechanisms ensure the digestion process remains safe under all operating conditions, even with demanding sample types or high-pressure digestion profiles.

Applications of High-Performance Microwave Digestion Instruments

A wide range of analytical laboratories benefit from the accuracy and efficiency of modern microwave digestion systems.

Key application fields:

* Environmental analysis: water, soil, sediment, and hazardous waste

* Food industry: trace metals, additives, nutrient analysis

* Pharmaceuticals: API verification, impurity analysis, herbal materials

* Mining and metallurgy: ore, alloys, precious metals

* Petrochemicals: lubricants, crude oil, polymers

* Biological samples: tissues, blood, plants

Efficient sample preparation ensures higher accuracy in downstream ICP-OES, ICP-MS, AAS, and ion chromatography measurements.

Operational Workflow for Microwave Digestion Systems

To achieve optimal digestion performance, laboratories follow a well-defined operation sequence:

1. Sample weighing and reagent addition

2. Proper vessel sealing and placement

3. Method selection or method programming

4. Automated digestion process with real-time monitoring

5. Cooling stage and safe vessel opening

6. Dilution and transfer for analytical measurement

Automation reduces operator workload, minimizes human error, and ensures that even complex digestion protocols can be executed with high consistency across batches.

User Value and Laboratory Benefits

Investing in a high-performance microwave digestion system delivers key advantages:

* Higher throughput for routine testing labs

* Shorter digestion cycles compared to traditional thermal methods

* Lower risk of contamination due to closed-vessel digestion

* Improved accuracy for trace and ultra-trace elemental analysis

* Extended method versatility with programmable protocols

* Stronger safety assurance compared to outdated digestion systems

The system not only enhances analytical accuracy but also supports fast, standardized, and compliant laboratory workflows.

Conclusion

A high-performance microwave digestion system is an essential instrument for laboratories seeking consistent, efficient, and safe sample preparation. With batch capacity up to 40 vessels, intelligent vessel design, real-time contactless monitoring, extensive method storage, and multi-level safety architecture, the system supports superior digestion quality for a broad range of analytical applications.

www.metashcorp.com

METASH