Custom car builds place fundamentally different demands on aluminum automotive parts compared with mass-production OEM programs. Tolerances are tighter, structural loads are less predictable, design iterations are frequent, and post-machining flexibility often matters as much as as-cast performance. Under these conditions, choosing between aluminum die-casting and aluminum gravity casting becomes a strategic engineering decision rather than a cost-only comparison.

This article provides a practical, engineering-level comparison of aluminum die-casting versus aluminum gravity casting for custom automotive parts, based on Tiger Casting’s long-term production experience across export markets such as the United States, Germany, and Japan. The focus is not on textbook definitions, but on how each process performs under real custom-build constraints.

1. Structural Integrity Under Non-Standard Load Conditions

Custom vehicles often introduce asymmetric loading, modified mounting points, and non-OEM stress paths. In these scenarios, internal material integrity becomes a primary differentiator.

Aluminum gravity casting generally delivers:

-

Lower internal stress concentration

-

Reduced risk of gas entrapment

-

More predictable grain structure in thicker cross-sections

This makes gravity-cast components particularly suitable for:

-

Suspension brackets

-

Engine mounting arms

-

Custom transmission housings

By contrast, aluminum die-casting excels in:

-

Thin-wall structural parts

-

Complex rib geometries

-

Weight-optimized enclosures

However, die-cast parts require stricter process control to manage porosity risk, especially when parts undergo secondary CNC machining. Tiger Casting mitigates this through X-ray inspection and tensile testing, ensuring that die-cast components used in custom builds meet mechanical reliability thresholds.

2. Dimensional Accuracy vs Machining Freedom

Custom automotive projects frequently require post-casting modifications, tight fits, and iterative design changes.

Die-casting advantages:

-

Superior dimensional repeatability

-

Excellent surface finish straight out of the mold

-

Reduced machining time for cosmetic or enclosure components

Gravity casting advantages:

-

Greater machining allowance

-

Lower risk of cutting into porosity zones

-

Better suitability for deep drilling, tapping, and re-profiling

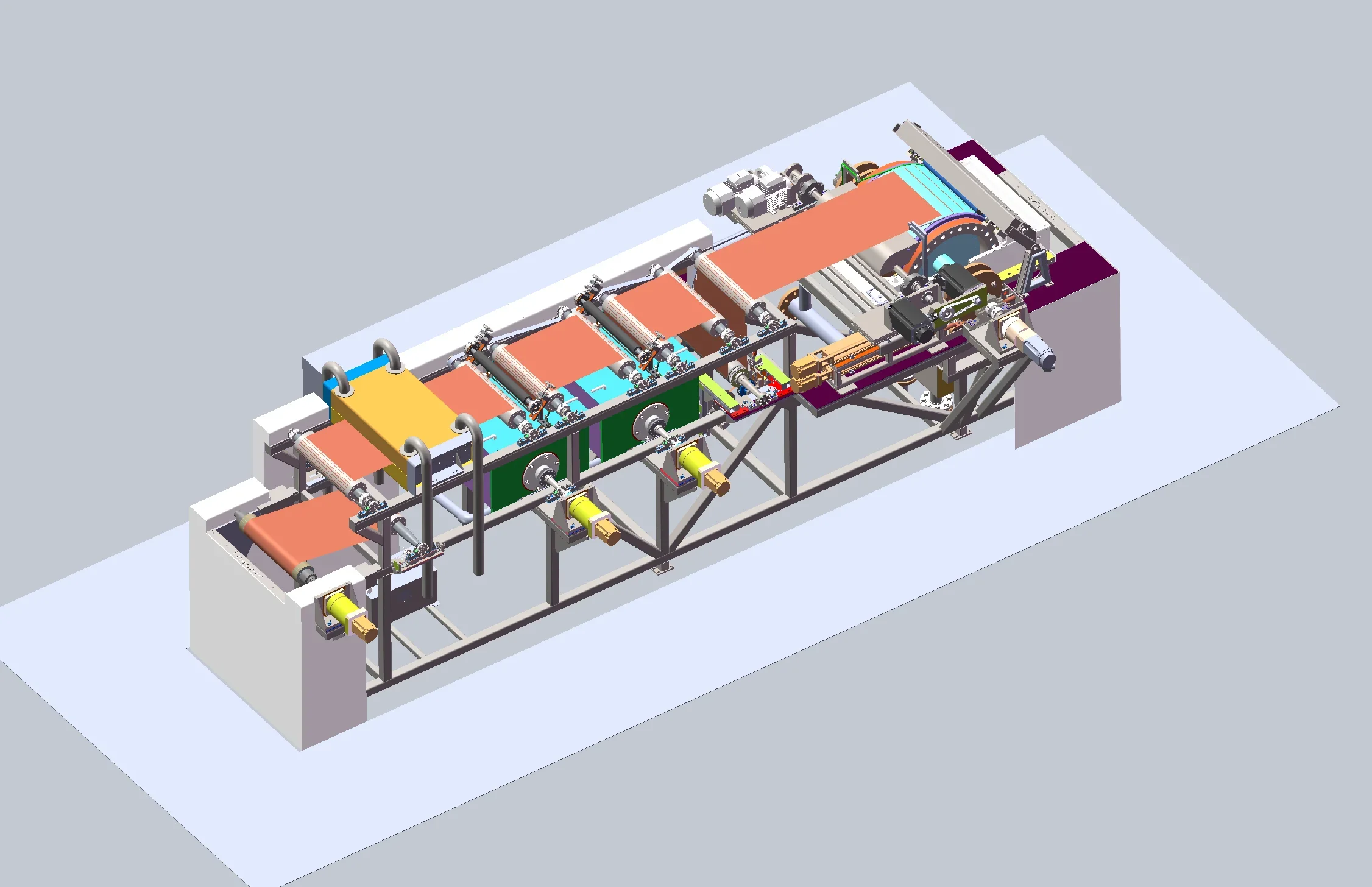

Tiger Casting’s production lines integrate high-precision CNC machining centers and CNC lathes, allowing both casting methods to be adapted for custom tolerances. However, gravity-cast aluminum parts typically offer greater long-term machining flexibility, which is often decisive in prototype-driven car builds.

3. Wall Thickness, Weight, and Thermal Behavior

Automotive custom parts frequently interact with heat—whether from engines, braking systems, or exhaust proximity.

-

Die-casting supports thinner wall sections (often below 3 mm), enabling lightweight designs with integrated cooling ribs.

-

Gravity casting performs better in thicker geometries, providing more stable thermal mass and lower risk of hot cracking.

Industry data from international aluminum associations indicates that gravity-cast aluminum components exhibit up to 20–25% better thermal fatigue resistance in high-temperature automotive environments when wall thickness exceeds 6 mm.

Tiger Casting’s material verification using spectrometers and hardness meters ensures alloy consistency for both processes, supporting predictable thermal behavior under custom vehicle conditions.

4. Surface Quality vs Functional Robustness

In custom automotive builds, some parts are visually exposed while others are purely functional.

-

Die-cast parts offer smoother as-cast surfaces, ideal for visible components such as lighting housings or interior structural brackets.

-

Gravity-cast parts prioritize internal soundness over cosmetic perfection, making them suitable for hidden load-bearing applications.

Tiger Casting’s finishing capabilities—polishing, shot blasting, and surface treatment—allow both casting types to meet appearance requirements without compromising functional integrity.

5. Leak Tightness and Pressure-Sensitive Components

For custom fuel systems, cooling systems, or hydraulic applications, leak integrity is non-negotiable.

Die-cast parts can achieve excellent leak performance only when process parameters and alloy selection are tightly controlled. Tiger Casting addresses this by deploying self-designed leak test machines, particularly for automotive fluid-handling components.

Gravity casting naturally reduces micro-porosity risks, often making it the safer choice for:

-

Oil channels

-

Coolant housings

-

Custom fluid manifolds

6. Production Flexibility for Custom and Low-Volume Builds

Unlike standard automotive programs, custom car builds often involve:

-

Small batch sizes

-

Design changes mid-project

-

Multiple revisions before finalization

Gravity casting offers:

-

Lower tooling rigidity

-

Easier mold modification

-

Better adaptability for iterative engineering

Die-casting becomes advantageous when:

-

Design is frozen

-

Geometry is highly complex

-

Surface consistency is critical

Tiger Casting’s hybrid production capability allows clients to transition from gravity-cast prototypes to die-cast series parts without changing suppliers, maintaining consistency across development phases.

7. Quality Verification as a Decision Factor

Casting method selection is only as reliable as the inspection infrastructure behind it.

Tiger Casting’s in-house quality system includes:

-

Spectrometer analysis for alloy composition

-

Tensile testing for mechanical validation

-

X-ray inspection for internal defect detection

-

Roughness and hardness measurement

-

Dimensional verification via measuring projectors

This enables data-driven selection between die-casting and gravity casting based on actual performance metrics, not assumptions.

8. Practical Selection Logic for Custom Automotive Parts

Rather than asking which process is “better,” experienced builders ask which process aligns with functional priorities:

| Design Priority | Recommended Process |

|---|---|

| Thin walls, complex ribs | Aluminum die-casting |

| High structural load | Aluminum gravity casting |

| Extensive CNC machining | Aluminum gravity casting |

| Visual surface quality | Aluminum die-casting |

| Low-volume flexibility | Aluminum gravity casting |

FAQ: Aluminum Casting Choices for Custom Car Builds

Q1: Can die-cast aluminum parts be safely CNC machined?

Yes, provided porosity is controlled through alloy selection and verified by X-ray inspection, as practiced by Tiger Casting.

Q2: Is gravity casting outdated for automotive use?

No. Gravity casting remains critical for structurally demanding and thermally loaded automotive components.

Q3: Can one supplier handle both processes consistently?

Yes. Tiger Casting integrates die-casting, gravity casting, machining, and inspection under one quality system, ensuring continuity.

Final Engineering Perspective

For custom automotive builds, aluminum die-casting and aluminum gravity casting are not competing technologies—they are complementary tools. The practical comparison lies in structural demands, machining requirements, thermal exposure, and production flexibility, all of which Tiger Casting is equipped to address through integrated manufacturing and inspection capabilities.

Selecting the correct casting method early in the design phase significantly reduces downstream risk, rework, and performance compromise—especially in high-expectation custom vehicle projects.

www.tiger-aluminumcasting.com

NINGBO TIGER CASTING COMPANY