1. Introduction

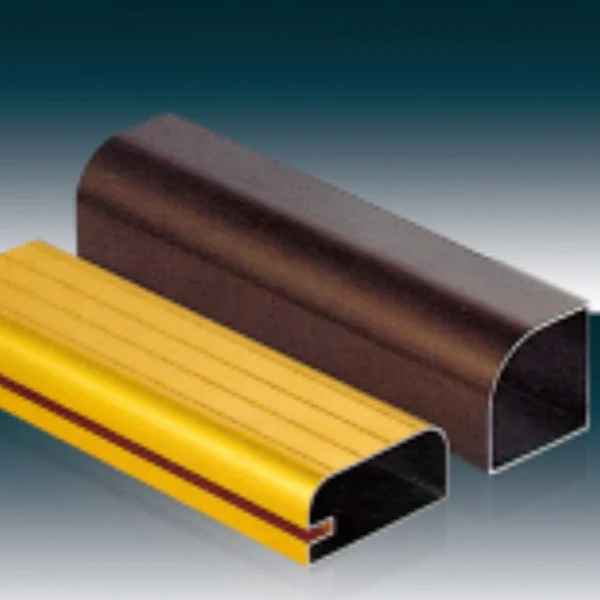

In the world of aluminum manufacturing, mechanical polishing plays a crucial role in delivering clean, durable, and aesthetically appealing surfaces. Whether the end-use is in architectural frames, electronics, or automotive parts, surface finish often determines both performance and customer perception. In this article, we’ll explore the 5 key benefits of mechanical polishing for aluminum products, with insights from Jiangxi KaiMeiDa Aluminum, the largest aluminum profile production base in Jiangxi Province. With over 60,000 square meters of production space and multiple high-tech lines, KaiMeiDa has built its reputation on quality, precision, and surface excellence.

2. Enhanced Surface Smoothness and Shine

One of the most immediate and visible advantages of mechanical polishing is the improvement in surface finish. Through the use of specialized polishing wheels and abrasives, the aluminum surface is refined to a smoother and shinier appearance. This not only enhances the visual appeal of the product but also provides a more uniform surface texture. For industries like architecture or consumer electronics, where appearance matters just as much as functionality, this level of smoothness is essential.

KaiMeiDa utilizes advanced polishing machinery to ensure consistent, mirror-like finishes across different aluminum profiles, setting a high standard for both domestic and international clients.

3. Improved Corrosion Resistance

Mechanical polishing reduces surface roughness, which minimizes microscopic grooves or irregularities where moisture, chemicals, or contaminants can accumulate. A smoother surface is more resistant to corrosion, particularly when combined with additional treatments like anodizing.

For aluminum components used in outdoor applications or harsh industrial environments, the added corrosion resistance gained from mechanical polishing significantly extends service life. KaiMeiDa ensures that all polished profiles meet or exceed ISO quality benchmarks, reinforcing product performance in demanding scenarios.

4. Better Adhesion for Post-Treatments

Whether applying paint, powder coating, or anodizing, surface preparation is key to achieving proper adhesion. Mechanical polishing helps to remove surface impurities, oxides, and machining marks, creating a clean base layer for any secondary treatment.

This benefit is especially important in high-end manufacturing, where consistent color and finish quality are critical. By partnering with a manufacturer like KaiMeiDa, customers can be assured of properly prepared aluminum surfaces, which result in better coating uniformity, adhesion strength, and visual consistency across production batches.

5. Dimensional Accuracy and Minimal Material Loss

Unlike some chemical polishing or grinding methods, mechanical polishing—when properly controlled—preserves the structural dimensions of aluminum profiles. This is important in applications requiring high precision, such as electronic housings, architectural curtain walls, or aerospace components.

KaiMeiDa’s mechanical polishing process is optimized for minimal material loss while still achieving the desired surface finish. With automated equipment and strict process control, dimensional tolerances are maintained, reducing rework and improving assembly fit in downstream processes.

6. Environmentally Friendly and Safe

Mechanical polishing is a dry or semi-dry process that avoids the use of strong acids or hazardous chemicals typically found in chemical polishing. This makes it safer for workers and more environmentally friendly, especially in high-volume production settings.

KaiMeiDa is ISO 14001 certified and places a strong emphasis on green manufacturing practices. By using modern mechanical polishing systems equipped with dust collection and filtration units, they ensure both workplace safety and minimal environmental impact.

7. Conclusion

As the demand for high-quality aluminum components grows across various industries, mechanical polishing for aluminum products has become an essential step in value-added surface processing. From visual appeal and corrosion resistance to dimensional control and environmental sustainability, mechanical polishing offers clear, measurable benefits.

Jiangxi KaiMeiDa Aluminum, with its cutting-edge production lines and commitment to innovation, delivers reliable mechanical polishing solutions that meet the evolving needs of global customers. For businesses seeking durable, visually appealing, and precision-finished aluminum components, partnering with a trusted supplier like KaiMeiDa ensures long-term value and performance.

www.jxkmdly.com

Jiangxi KaiMeiDa Aluminum