Selecting the right dry oil-free screw compressor is a critical decision for industrial facilities, laboratories, and production lines where clean, contaminant-free compressed air is essential. From pharmaceuticals to electronics manufacturing, the demand for high-quality, reliable, and energy-efficient compressed air systems is higher than ever. This guide will walk you through the key factors to consider when choosing a dry oil-free screw compressor, with insights drawn from industry leaders like SMEATON Fluid Machinery (Shanghai) Co., Ltd., a company renowned for delivering advanced fluid machinery solutions.

What Is a Dry Oil-Free Screw Compressor?

A dry oil-free screw compressor is a type of rotary screw compressor that compresses air without the use of lubricating oil in the compression chamber. Unlike traditional lubricated compressors, oil does not come into contact with the compressed air, ensuring that the output is 100% free from oil contamination.

This makes dry oil-free compressors ideal for industries with stringent air quality requirements, such as:

-

Pharmaceutical manufacturing

-

Food and beverage production

-

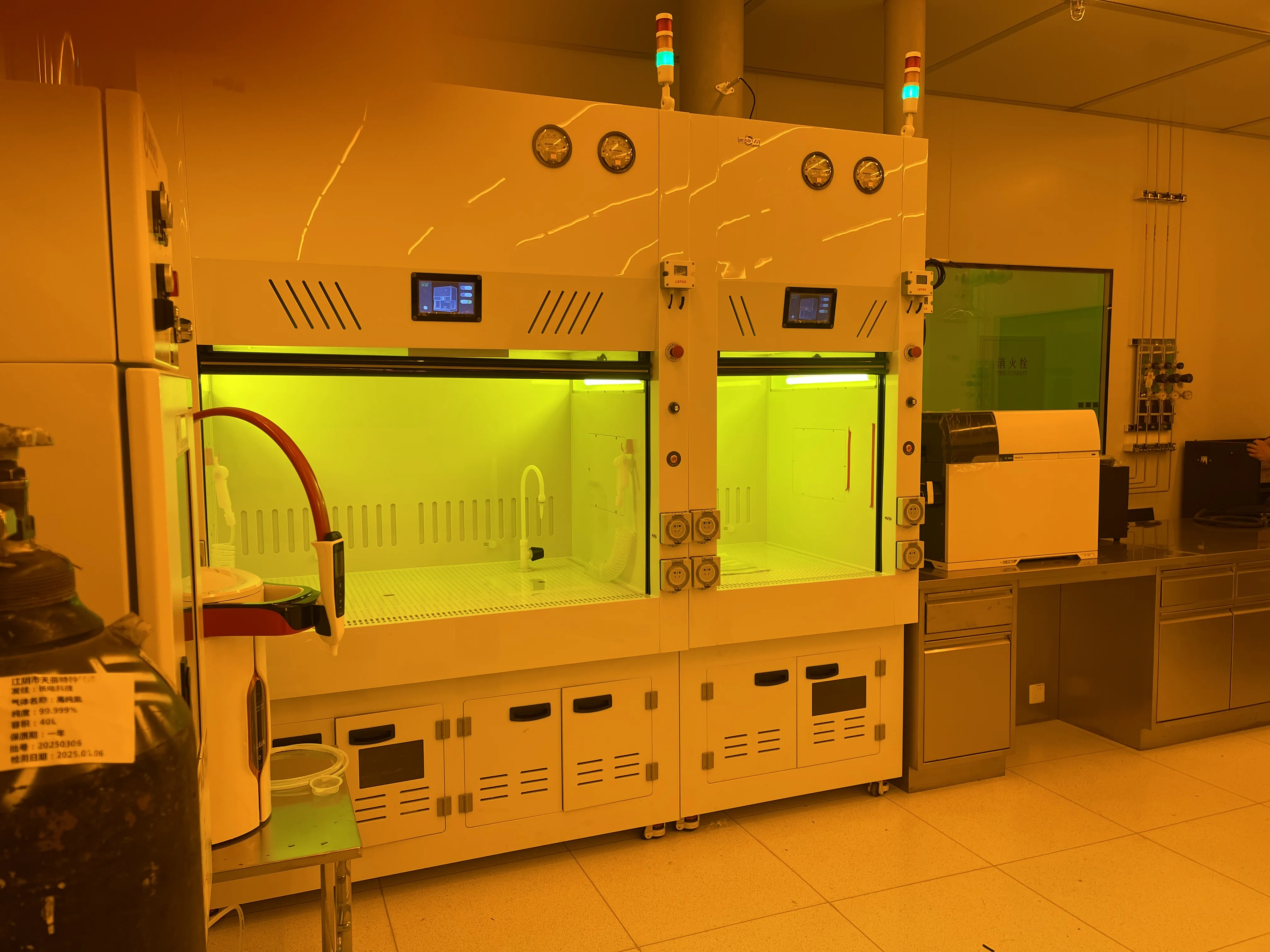

Electronics and semiconductor manufacturing

-

Medical and laboratory applications

The “dry” nature of these compressors also simplifies maintenance in certain aspects, as there is no need to manage oil contamination or filtration systems, though regular monitoring and servicing are still critical.

Key Factors to Consider When Choosing a Dry Oil-Free Screw Compressor

1. Air Quality Requirements

The primary reason to choose a dry oil-free screw compressor is the need for uncontaminated air. Check the ISO air quality standards required for your facility. For example, pharmaceutical and food-grade applications often require ISO Class 0, which ensures zero oil content in the compressed air.

2. Capacity and Flow Rate

Assess your facility’s compressed air demand in terms of cubic meters per minute (m³/min) or cubic feet per minute (CFM). Oversizing a compressor can lead to higher initial costs and energy waste, while undersizing can compromise operations. Companies like SMEATON provide customized solutions to optimize compressor size based on actual demand, including variable speed options for dynamic load adjustment.

3. Pressure Requirements

Different processes require different pressure levels. Dry oil-free screw compressors can generally handle pressures ranging from 5 to 13 bar, but it is essential to match the unit to your operational needs. High-pressure applications may require specialized models to maintain efficiency and safety.

4. Energy Efficiency and Sustainability

Compressed air systems can account for a significant portion of a facility’s energy consumption. Look for compressors with energy-saving features, such as:

-

Heat recovery systems to capture and reuse waste heat

-

Variable speed drives (VSD) to adjust output based on real-time demand

-

High-efficiency motors and optimized screw profiles

SMEATON offers services such as energy efficiency assessment (EEA) and contract energy management (EMC) to help facilities minimize energy costs and environmental impact.

5. Maintenance and Reliability

Even oil-free compressors require regular maintenance, including checking bearings, cooling systems, and airend integrity. Choose a reliable manufacturer that provides robust after-sales support, spare parts availability, and training. SMEATON’s global service network ensures that customers receive timely support, maintenance guidance, and performance optimization.

6. Integration with Existing Systems

Many facilities integrate compressors with air treatment systems, storage tanks, and pneumatic equipment. Ensure the compressor is compatible with your existing infrastructure. Advanced suppliers like SMEATON also offer turnkey solutions, including contracted air supply (ASC), system optimization, and energy recovery solutions, providing seamless integration and long-term efficiency.

Advantages of Choosing a Reputable Supplier

Working with a trusted provider like SMEATON Fluid Machinery (Shanghai) Co., Ltd. offers multiple benefits:

-

Comprehensive Product Range: From dry oil-free and oil-injected screw compressors to centrifugal compressors, blowers, and vacuum pumps.

-

Customized Solutions: Tailored equipment for specific industrial needs, including heat recovery, energy optimization, and facility-specific designs.

-

Global Expertise: A combination of international standards, local service, and operational guidance ensures reliable, long-term performance.

By partnering with an experienced supplier, facilities can achieve higher uptime, reduced energy costs, and compliance with industry standards for air quality and environmental sustainability.

Conclusion

Choosing the right dry oil-free screw compressor is a strategic decision that impacts both operational efficiency and product quality. Consider air quality requirements, capacity, pressure, energy efficiency, maintenance, and integration with existing systems when making your selection.

With advanced solutions from companies like SMEATON Fluid Machinery, facilities can not only secure reliable, high-performance dry oil-free compressors but also optimize energy usage, integrate advanced air systems, and achieve long-term operational savings. Investing in the right compressor ensures clean, safe, and efficient air for critical applications, supporting sustainable and high-performance operations across industries.

www.smeatoncompressor.com

SMEATON Fluid Machinery (Shanghai) Co., Ltd.