Electrodeposited copper foil plays an essential role in various high-technology industries, especially in the production of lithium-ion batteries, printed circuit boards (PCBs), and electromagnetic shielding materials. As demand for high-performance copper foil continues to rise, the precision, efficiency, and stability of production equipment have become central to ensuring consistent product quality. This article provides an in-depth overview of electrodeposited copper foil production equipment and highlights the technological expertise of Timonic, a company dedicated to advancing lithium battery material production systems and complete copper foil manufacturing solutions.

Understanding Electrodeposited Copper Foil

Electrodeposited (ED) copper foil is produced by electrochemically depositing copper ions onto a rotating titanium drum (known as the cathode roller) in an electrolytic bath. This process allows for the creation of ultra-thin, high-purity copper films with precise thickness control and uniform surface properties. The resulting copper foil is widely used as a current collector in lithium-ion batteries and as a conductive layer in printed circuit boards.

The quality of electrodeposited copper foil depends heavily on the precision of the production equipment and the stability of electrochemical processes. Every parameter—from electrolyte composition to current density, temperature control, and drum surface roughness—must be carefully managed to ensure consistent foil performance.

Key Equipment in Copper Foil Production

The production of electrodeposited copper foil involves several major pieces of equipment, each performing a critical role in the process chain:

Electrolytic Deposition Unit

This is the heart of the copper foil production line. It includes the electrolytic cell, cathode drum, and anode system. Copper ions are reduced and deposited onto the drum’s surface as it rotates through the electrolyte. The uniformity of the electric field and precise temperature control ensure consistent foil thickness and smooth surface quality.

Peeling and Washing Systems

After deposition, the thin copper layer is peeled off the drum surface and immediately washed to remove residual electrolytes and impurities. Automated peeling mechanisms ensure continuous production and prevent damage to the delicate foil.

Surface Treatment and Coating Units

Copper foils undergo roughening, oxidation, or chemical coating to enhance adhesion with battery or PCB substrates. These surface treatments are essential to achieving optimal performance in downstream applications.

Drying and Tension Control Systems

Uniform drying and precise tension management prevent wrinkling or tearing during foil handling. Advanced tension feedback systems ensure smooth transportation through the production line.

Slitting, Rolling, and Packaging Equipment

Finished copper foils are slit to specific widths, rolled, and packaged according to customer requirements. These processes demand precise alignment and surface protection to maintain product integrity.

Importance of Precision and Automation

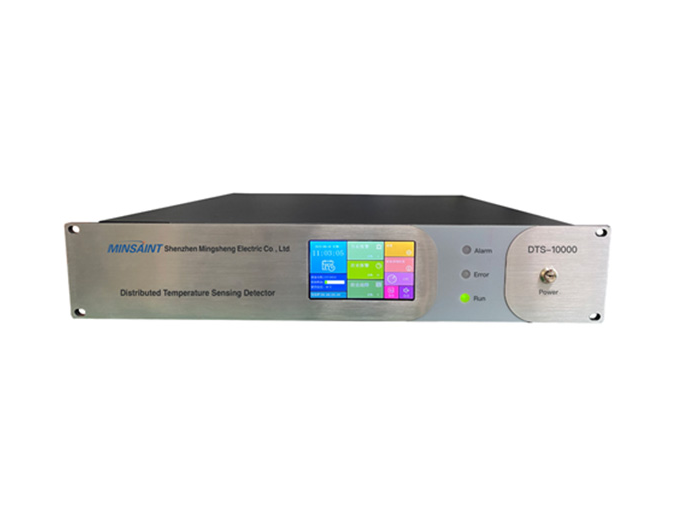

Producing high-quality electrodeposited copper foil requires extreme precision. Even microscopic inconsistencies in deposition thickness or surface treatment can significantly impact the performance of lithium-ion batteries or electronic components. Therefore, modern production lines are equipped with intelligent monitoring systems, real-time feedback controls, and automated fault detection.

Automation not only improves consistency but also enhances safety and operational efficiency. The integration of mechanical, electrical, and software systems allows for seamless coordination across different stages of production, reducing manual errors and ensuring stable output over long production cycles.

Timonic: Excellence in Lithium Battery Copper Foil Production Equipment

Timonic is a leading company dedicated to the research, development, and manufacturing of advanced equipment for the production of materials used in the new energy sector, particularly lithium battery copper foil. The company specializes in copper foil manufacturing machines, cathode rollers, and complete turnkey solutions for high-quality lithium battery copper foil factories.

With strong expertise in electromechanical integration and automation, Timonic provides one-stop design and engineering services for copper foil production lines. Its comprehensive offerings include intelligent equipment systems, hardware and software integration, and customized automation solutions tailored to client requirements. By combining precision engineering, advanced control systems, and robust technical support, Timonic ensures stable, high-efficiency, and high-yield copper foil production.

Timonic’s products are widely recognized for their exceptional performance, durability, and ease of maintenance. The company’s ability to deliver both individual equipment units and full production line setups enables manufacturers to achieve high operational reliability and consistent product quality.

Conclusion

The production of electrodeposited copper foil demands a perfect balance of electrochemical expertise, mechanical precision, and intelligent automation. High-performance equipment ensures the uniformity, stability, and reliability required for use in lithium-ion batteries and advanced electronic components. With its deep technical know-how and integrated solutions, Timonic continues to play a pivotal role in supporting the efficient and high-quality production of lithium battery copper foil, contributing to

Understanding Electrodeposited Copper Foil Equipment: Applications and Key Features

www.timonic.com.cn

Timonic