As global photovoltaic (PV) installations continue to expand at an unprecedented pace, system safety, reliability, and lifecycle cost have become just as critical as power generation efficiency. One key but often underestimated component is copper clad steel strand wire for PV system, which plays a decisive role in grounding, earthing, and lightning protection. In this article, we will explore what copper clad steel strand wire is, why it is essential for PV systems, and how Sunlightweld copper clad steel strand wire for PV system delivers superior performance, durability, and cost efficiency for solar projects worldwide.

Why Grounding and Lightning Protection Matter in PV Systems

PV systems are typically installed in open, exposed environments—rooftops, deserts, mountains, and coastal areas—making them vulnerable to:

•Lightning strikes

•Ground faults and surge currents

•Corrosion from moisture, salt, or chemicals

•Mechanical stress caused by wind and temperature variation

A reliable grounding and lightning protection system is therefore not optional—it is fundamental to protecting equipment, ensuring personnel safety, and meeting international standards such as IEC, IEEE, and NEC.

This is where copper clad steel strand wire for PV system becomes the preferred solution.

What Is Copper Clad Steel Strand Wire for PV System?

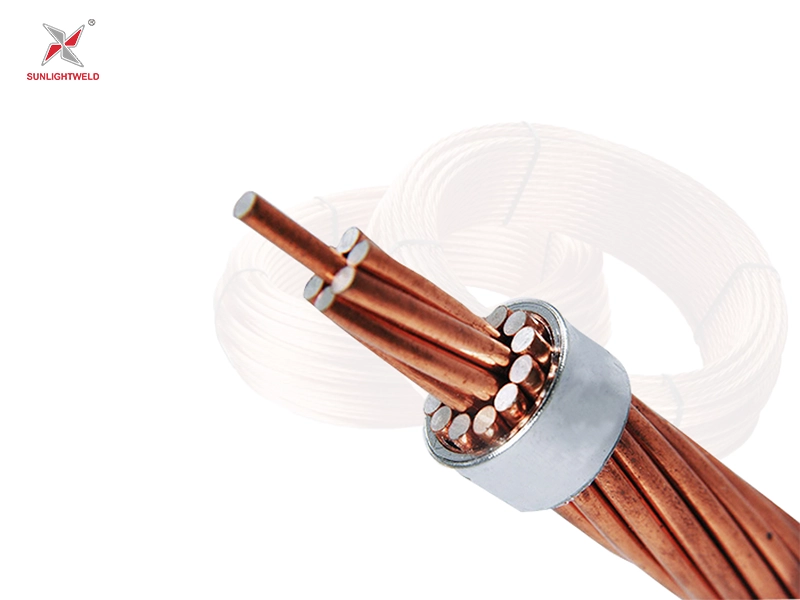

Copper clad steel strand wire for PV system is a composite grounding conductor manufactured by permanently bonding a high-purity copper layer onto a high-strength steel core through a metallurgical process rather than simple electroplating or surface coating. This true copper-to-steel bonding ensures excellent electrical continuity, mechanical durability, and long-term performance. In photovoltaic grounding applications, this structure delivers a balanced combination of high electrical conductivity for effective lightning and fault current dissipation, superior tensile strength to withstand mechanical stress, enhanced corrosion resistance for outdoor environments, and a lower total cost of ownership compared to solid copper conductors, making it an ideal solution for large-scale and long-life PV systems.

Sunlightweld Copper Clad Steel Strand Wire for PV System Advantages

1. Excellent Electrical Conductivity (Customizable)

Through advanced copper bonding technology, Sunlightweld copper clad steel strand wire for PV system delivers high and stable electrical conductivity, making it highly suitable for PV grounding grids, equipment earthing conductors, and lightning protection down conductors. The copper layer ensures efficient fault current dissipation and reliable lightning energy conduction, while copper thickness and conductivity levels can be customized based on specific project requirements. This allows EPC contractors and system designers to achieve optimal electrical performance without unnecessary material cost, ensuring both technical reliability and economic efficiency.

2. Enhanced Mechanical Strength for Easy Installation

The high-strength steel core used in Sunlightweld copper clad steel strand wire for PV system provides significantly greater tensile strength compared to traditional pure copper conductors. This structural advantage allows for easier handling during long-distance installation, reduces the risk of breakage or deformation, and ensures stable performance in harsh environments such as deserts, offshore PV plants, and high-wind regions. For large-scale solar power projects, this enhanced mechanical strength translates into faster installation, improved construction safety, and lower overall labor costs.

3. Superior Corrosion Resistance for Long-Term Reliability

Designed to support the long service life of photovoltaic systems, Sunlightweld copper clad steel strand wire for PV system offers excellent corrosion resistance for long-term reliability. The bonded copper layer acts as a natural barrier against corrosion, effectively resisting soil chemicals, moisture, and salt spray. Even in coastal, high-humidity, or chemically aggressive environments, the conductor maintains stable electrical performance, ensuring long-term grounding continuity and minimal maintenance throughout the entire project lifecycle.

4. High Cost-Effectiveness: Save 30%–50% on Material Cost

One of the key advantages of Sunlightweld copper clad steel strand wire for PV system is its outstanding cost-effectiveness. Benefiting from factory-direct supply and optimized manufacturing processes in China, customers can typically achieve material cost savings of 30%–50% compared to solid copper conductors or international brands, without compromising on quality, performance, or compliance with relevant standards. These cost savings directly improve project ROI and enhance EPC profitability, especially in large-scale PV installations.

5. Fully Customized Solutions for Your PV Application

Every photovoltaic project has unique technical and environmental requirements, and Sunlightweld copper clad steel strand wire for PV system is designed to provide fully customized solutions. Available options include tailored strand structures and diameters, adjustable copper thickness, compliance with project-specific standards and certifications, and packaging optimized for on-site installation efficiency. This high level of customization ensures the conductor integrates seamlessly into each grounding and lightning protection design.

6. Professional Technical Support You Can Rely On

Sunlightweld is more than just a manufacturer; it is a trusted technical partner. With Sunlightweld copper clad steel strand wire for PV system, customers benefit from comprehensive technical support provided by an experienced engineering team, including product selection guidance, grounding system design assistance, installation recommendations, and fast responses to technical inquiries. This professional support minimizes project risk and ensures smooth implementation from the design phase through installation and final commissioning.

Why Choose Sunlightweld

Sunlightweld is a professional manufacturer and factory specializing in earthing materials, grounding products, and lightning protection systems for photovoltaic applications. Leveraging China's mature PV supply chain, we operate advanced production lines with strict quality control and international standards compliance, ensuring stable quality, flexible customization, and cost-efficient manufacturing. This integrated advantage enables faster delivery, scalable capacity, and up to 30% higher profit margins for global EPCs, distributors, and system integrators. Sunlightweld is committed to building long-term partnerships by providing reliable products, technical expertise, and competitive solutions for the global solar market.

Conclusion

For grounding and lightning protection applications, Sunlightweld copper clad steel strand wire for PV systems delivers an optimal balance of conductivity, mechanical strength, corrosion resistance, and cost efficiency. With high and customizable conductivity, superior durability, factory-direct pricing that achieves 30%–50% cost savings, and full customization backed by professional technical support, Sunlightweld provides reliable grounding solutions for long-term PV project performance. Contact Sunlightweld today to explore customized copper clad steel strand wire solutions and build a competitive advantage through our global partnership network.

https://www.sltup.com/Copper-Bonded-Steel-Stranded-Conductor-Factory-Price-and-Supplier.html

www.sltup.com

Sunlightweld