In the realm of mechanical engineering and automotive design, the lubrication system plays a pivotal role in ensuring the longevity and efficiency of engines and machinery. Among the critical parameters that govern the performance of these systems, oil pressure stands out as a vital factor. This article delves into the intricacies of what controls oil pressure inside lubrication systems, exploring the mechanisms, components, and implications of oil pressure regulation.

The Importance of Oil Pressure

Oil pressure is essential for maintaining a proper lubrication film between moving parts, reducing friction, and preventing wear and tear. Insufficient oil pressure can lead to catastrophic engine failure, while excessive pressure can cause leaks and damage seals. Therefore, understanding the factors that influence oil pressure is crucial for engineers, mechanics, and vehicle owners alike.

Key Components Influencing Oil Pressure

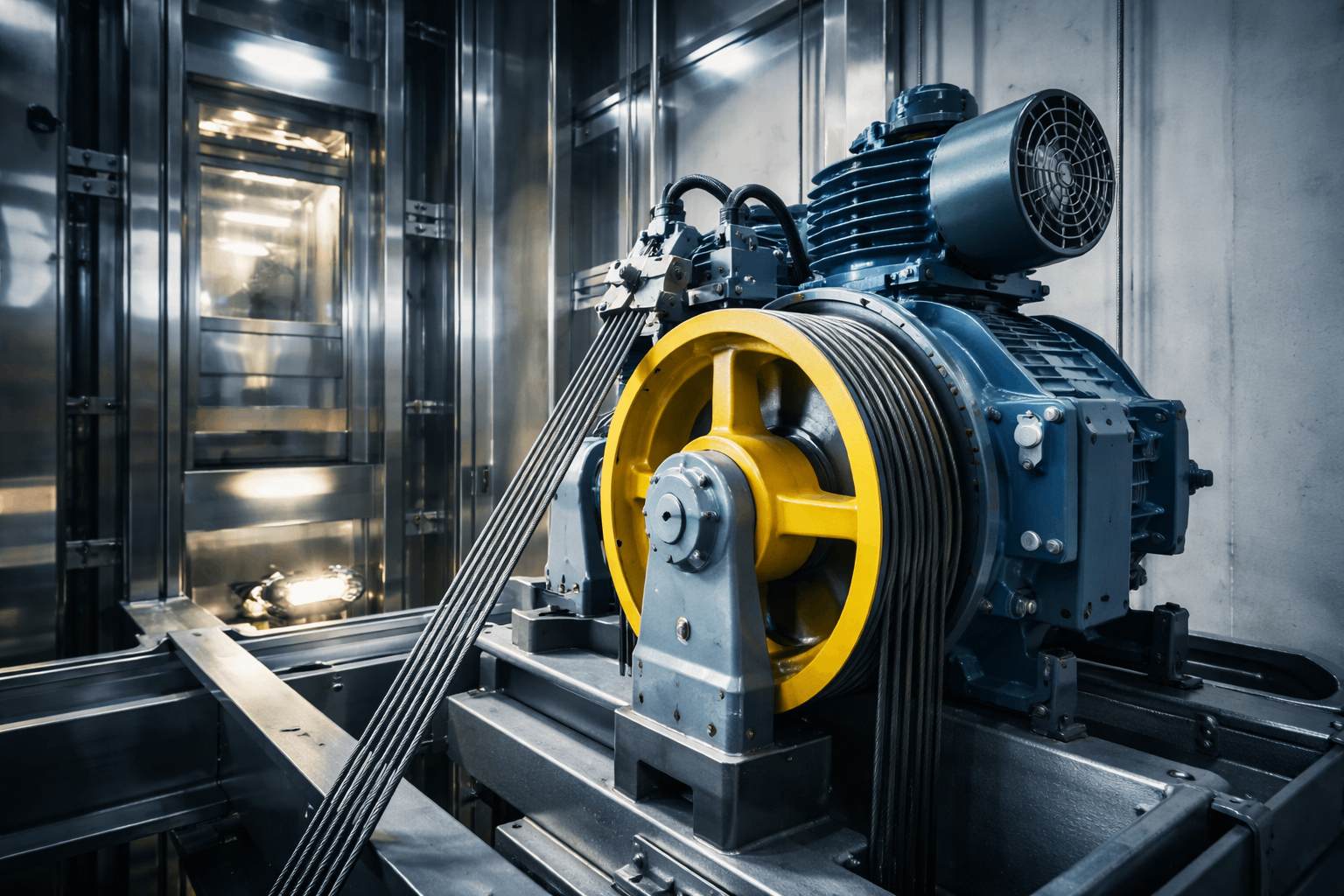

- Oil Pump: The heart of any lubrication system, the oil pump is responsible for circulating oil throughout the engine. The type of pump—gear, vane, or diaphragm—affects the pressure generated. Gear pumps, for instance, are commonly used in automotive applications due to their ability to maintain consistent pressure across varying engine speeds.

- Oil Viscosity: The viscosity of the oil plays a significant role in oil pressure. Thicker oils (higher viscosity) create more resistance to flow, which can lead to higher pressure readings. Conversely, thinner oils (lower viscosity) flow more easily, potentially resulting in lower pressure. It’s essential to select the appropriate oil viscosity based on the engine's operating conditions and manufacturer specifications.

- Oil Filter: The oil filter is designed to remove contaminants from the oil, but it can also impact oil pressure. A clogged filter can restrict oil flow, leading to increased pressure upstream and decreased pressure downstream. Regular maintenance and timely oil changes are vital to ensure the filter remains effective.

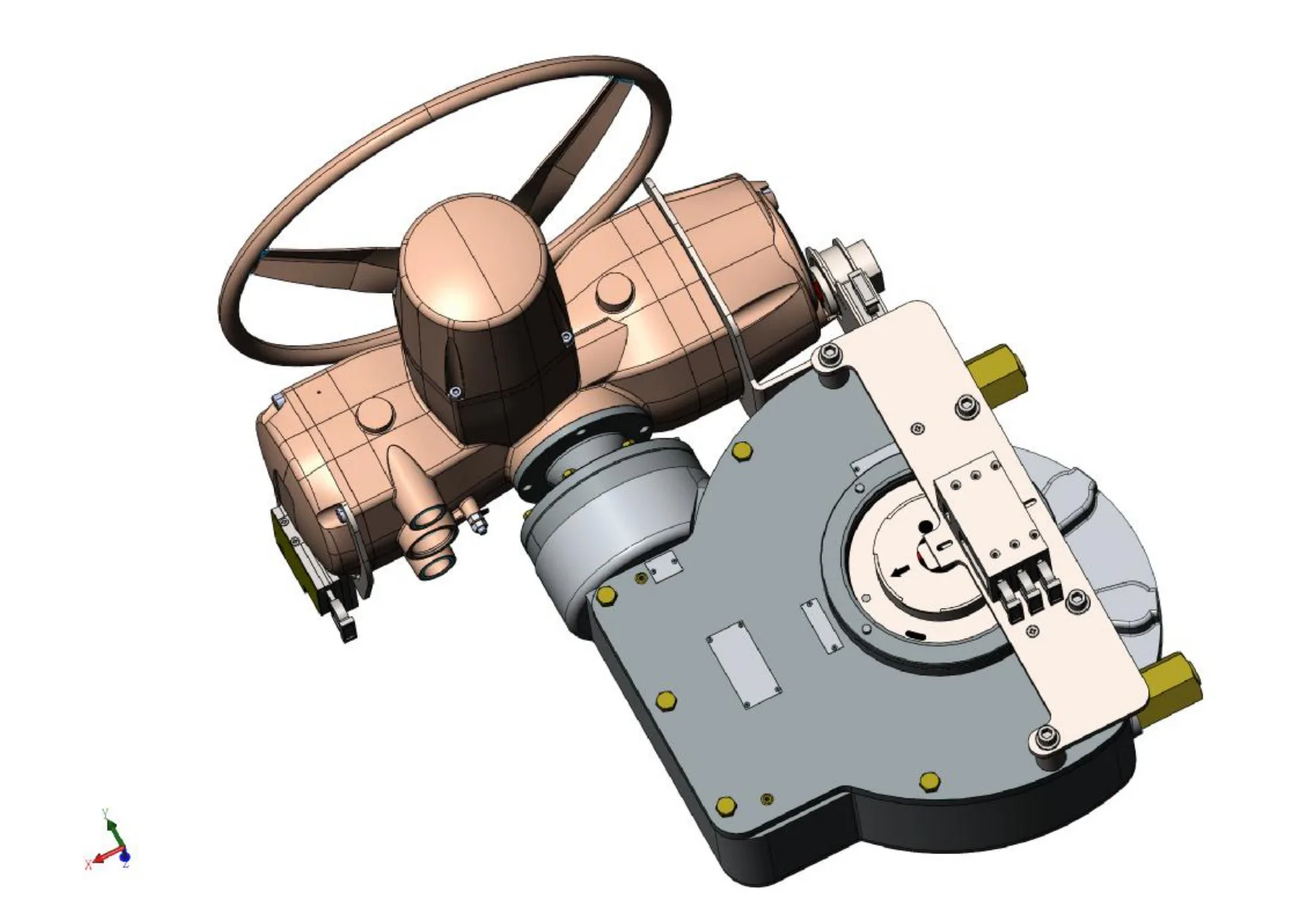

- Relief Valve: Most lubrication systems are equipped with a pressure relief valve that regulates oil pressure. This valve opens when the pressure exceeds a predetermined level, allowing excess oil to bypass the system and return to the oil pan. This mechanism prevents damage to the oil pump and other components due to excessive pressure.

- Engine Temperature: The operating temperature of the engine significantly affects oil viscosity and, consequently, oil pressure. As the engine heats up, oil thins, which can lead to lower pressure. Conversely, cold oil is thicker and can create higher pressure. Therefore, monitoring engine temperature is crucial for maintaining optimal oil pressure.

External Factors Affecting Oil Pressure

- Engine Speed: Oil pressure is directly related to engine speed. At higher RPMs, the oil pump generates more pressure due to increased centrifugal force. Conversely, at idle, oil pressure may drop. Understanding this relationship is essential for diagnosing potential issues in the lubrication system.

- Oil Level: Insufficient oil levels can lead to a drop in oil pressure. Regularly checking the oil level and topping it off as necessary is a simple yet effective way to maintain proper lubrication and pressure.

- Wear and Tear: Over time, engine components can wear down, leading to increased clearances between moving parts. This wear can result in lower oil pressure, as the oil can escape through these gaps more easily. Regular inspections and maintenance can help identify and mitigate these issues before they escalate.

Diagnosing Oil Pressure Issues

When faced with oil pressure problems, it’s essential to conduct a systematic diagnosis. Start by checking the oil level and condition, followed by inspecting the oil filter and pump. Utilizing an oil pressure gauge can provide accurate readings to determine if the pressure is within the acceptable range. If issues persist, further investigation into the relief valve and engine components may be necessary.

Conclusion

Understanding what controls oil pressure inside lubrication systems is crucial for maintaining engine performance and longevity. By recognizing the interplay between various components, external factors, and the importance of regular maintenance, engineers and vehicle owners can ensure optimal lubrication and prevent costly failures. As technology advances, ongoing education and adaptation will be key to mastering the complexities of lubrication systems and oil pressure management.