In the realm of modern manufacturing, precision and efficiency are paramount. Among the myriad of tools and machines that facilitate these objectives, spindle machines stand out for their versatility and capability. But what exactly is a spindle machine used for? This article delves into the multifaceted applications of spindle machines, exploring their significance across various industries, the technology behind them, and the innovations that continue to shape their evolution.

Understanding Spindle Machines

At its core, a spindle machine is a type of machine tool that utilizes a rotating spindle to perform various machining operations. The spindle serves as the primary axis of rotation, allowing for the attachment of different cutting tools or workpieces. This design enables spindle machines to execute a range of tasks, including drilling, milling, grinding, and turning, making them indispensable in manufacturing processes.

Key Applications of Spindle Machines

- Precision Machining: One of the primary uses of spindle machines is in precision machining. Industries such as aerospace, automotive, and medical device manufacturing rely on spindle machines to create intricate components with tight tolerances. The ability to maintain consistent speed and torque allows for high-quality finishes and dimensional accuracy.

- CNC Machining: Computer Numerical Control (CNC) spindle machines have revolutionized manufacturing by automating the machining process. These machines can be programmed to perform complex operations with minimal human intervention, significantly increasing productivity and reducing the likelihood of errors. CNC spindle machines are widely used in industries that require mass production of parts, such as electronics and consumer goods.

- Woodworking: In the woodworking industry, spindle machines are employed for tasks such as shaping, drilling, and sanding. The versatility of spindle machines allows woodworkers to create detailed designs and finishes, enhancing the aesthetic appeal of wooden products. Additionally, CNC spindle machines in woodworking have enabled the production of intricate patterns and custom designs with ease.

- Metalworking: Spindle machines play a crucial role in metalworking, where they are used for operations like turning and milling. The ability to switch out tools quickly and efficiently makes spindle machines ideal for creating complex metal parts, from automotive components to industrial machinery. The precision offered by these machines ensures that metal parts meet stringent quality standards.

- Textile Industry: In the textile sector, spindle machines are utilized for spinning and weaving processes. Spindle technology has evolved to enhance the efficiency of yarn production, allowing for the creation of high-quality fabrics. Modern spindle machines in textiles are designed to operate at high speeds, increasing output while maintaining quality.

Technological Innovations in Spindle Machines

The evolution of spindle machines has been marked by significant technological advancements. Here are some key innovations that have enhanced their functionality:

- High-Speed Spindles: The development of high-speed spindles has allowed for faster machining processes, reducing cycle times and increasing productivity. These spindles can operate at speeds exceeding 100,000 RPM, making them ideal for applications requiring fine finishes.

- Adaptive Control Systems: Modern spindle machines are equipped with adaptive control systems that monitor and adjust machining parameters in real-time. This technology optimizes performance by adapting to changes in material properties or tool wear, ensuring consistent quality throughout the production process.

- Multi-Spindle Machines: The introduction of multi-spindle machines has further increased efficiency in manufacturing. These machines can perform multiple operations simultaneously, significantly reducing production time and costs. They are particularly beneficial in high-volume production environments.

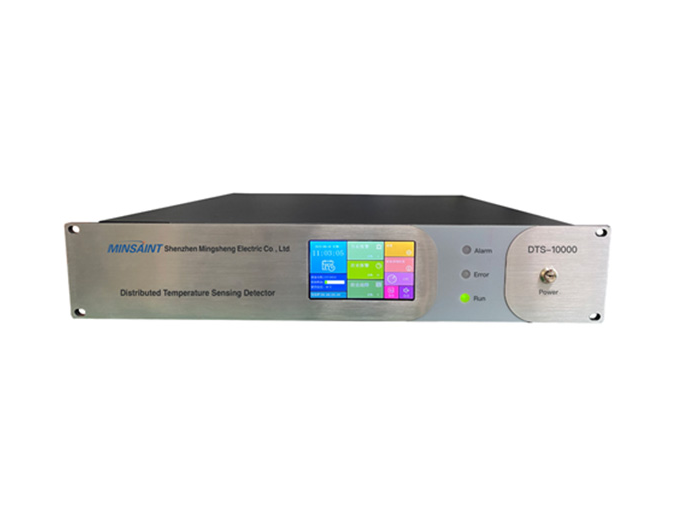

- Integration with IoT: The integration of Internet of Things (IoT) technology into spindle machines has enabled manufacturers to monitor machine performance remotely. This connectivity allows for predictive maintenance, reducing downtime and improving overall operational efficiency.

Conclusion

Spindle machines are a cornerstone of modern manufacturing, offering unparalleled versatility and precision across various industries. From aerospace to textiles, their applications are vast and varied, making them essential tools for producing high-quality components and products. As technology continues to advance, the capabilities of spindle machines will only expand, paving the way for even greater innovations in manufacturing processes. Understanding what spindle machines are used for not only highlights their importance but also underscores the ongoing evolution of manufacturing technology in our increasingly automated world.